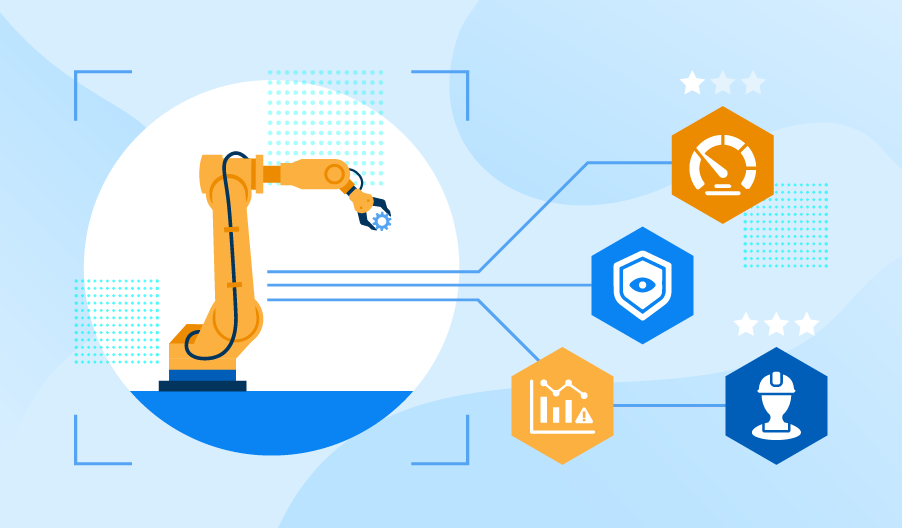

Monitor your vehicles, drivers, and trips in real time. View your vehicles location, costs of operation, usage, and driving behavior history.

Configure Fleets, Monitor Fleet and Shipment

Locate vehicle and shipments

Manage Incident and Alerts

This solution will display the instruction on how to perform a quality check and document the ticket. Capability to notify on specific conditions and viewing, commenting, changing status; assigning to engineer/station, prioritizing the tickets. Less downtime on production lines and lower losses. Leading to lower machine failure rates. Reports on the tickets statistics and quality.

Together we can plan the best roadmap for you so that every step of the way will lead to measurable effect and bring you closer to the ultimate goal.

Accelerate business operations and digital production planning based on facts & figures

Maximum productivity and production quality enables full utilization of available production capacity

Real time data availability, contextualized information, documents and work -instructions, data visualization and presentation.